Even if you want to keep your car indefinitely, at some point it will stop working. In Belgium, cars have an average lifespan of 16.4 years. After that, Febelauto will take the wheel, just as it has been doing since 1999! Febelauto organises, processes and recycles scrap vehicles in an environmentally friendly manner by using approved centres and crushing plants.

130 approved recycling centres

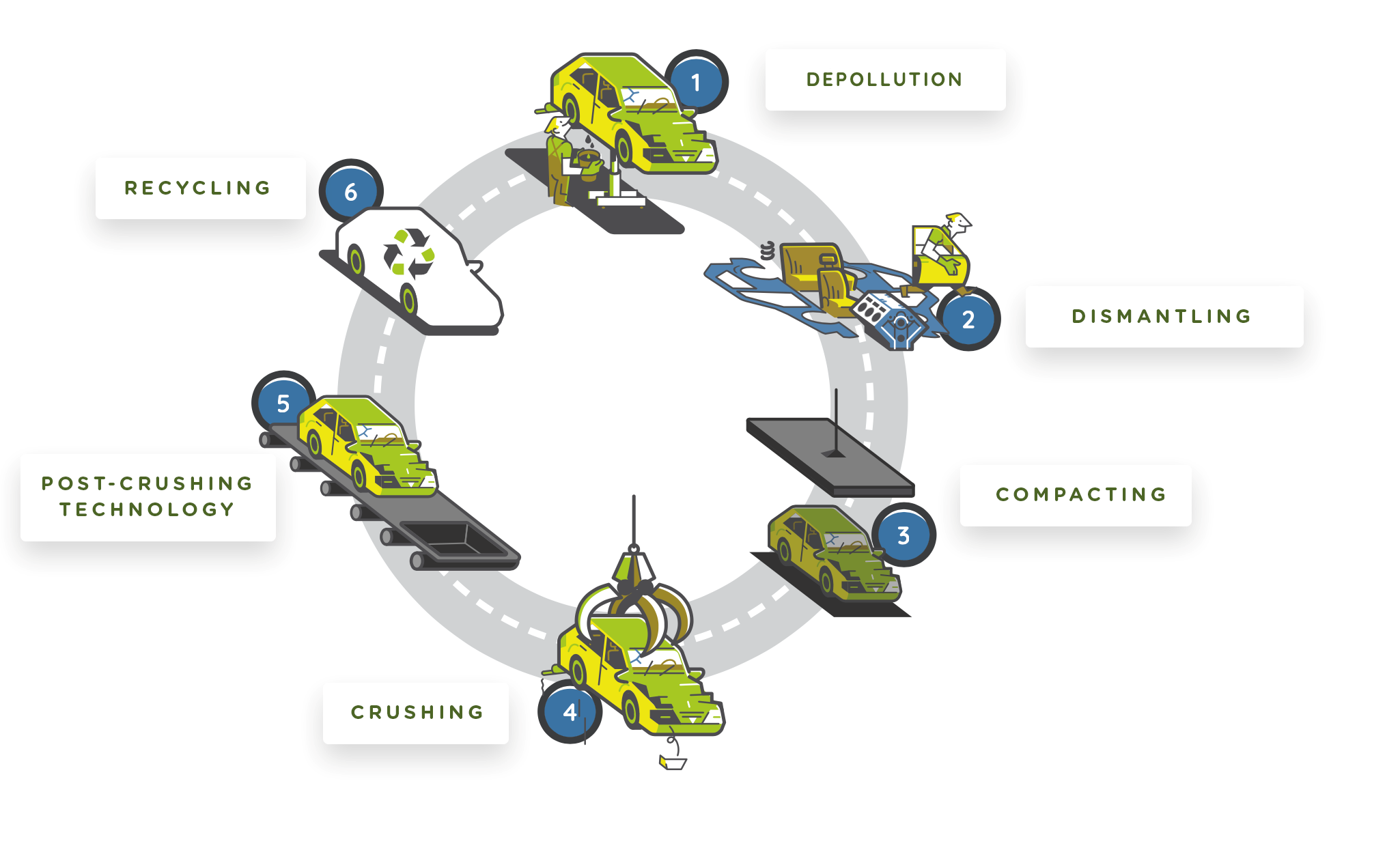

This is where in 2020, everything started again for 110,161 end-of-life vehicles. 97.3% of their vehicle weight could be reused, recycled or recovered. Belgium therefore exceeds the objective set under the European Directive and regional legislation, which imposes a 95% recovery standard for end-of-life vehicles. So that this great result can be achieved, various well-established steps have been put in place:

- Batteries and fluids such as fuel, brake fluid and antifreeze are removed.

- Reusable elements are dismantled (23.7%).

- It then takes just 12 seconds to crush the rest of the scrap vehicle.

- The waste then goes through 40 sorting techniques so that pure and distinct materials can be obtained.

Batteries get a new lease of life

Your electric and hybrid vehicles are equipped with batteries that are often lithium-ion. Specific procedures have to be followed for collecting and processing these batteries. Febelauto has therefore created the Watt4Ever consortium to help manage this process with the utmost care.

When they arrive at the processing centre, these batteries are dismantled into modules or even cells. Tests are carried out to see if these elements can be reused. Those that still work will be used in storage units; for example, to store surplus output from photovoltaic or wind installations. Otherwise, the raw materials will be extracted for reuse.

At the end of their second life, used batteries will be permanently recycled in accordance with European standards. Hydrometallurgy and pyrometallurgy systems are used to sort the various metals and rare earths; these are then resold to make new batteries.

Tyres can be recycled too!

Even if you can go almost all around the world with one set of tyres, you will probably need to change them one day. But don’t worry; used tyres aren’t just dumped or burned – over 95% of them are collected by Recytyre.

In 2018, this Belgian management organisation for worn tyres collected over 85 tonnes of car tyres. The tyres are converted into rubber granules that can be used as a basis for making new tyres or for making a new tread for an existing tyre. As for the steel from the tyre, the steel industry will take care of recycling this. The remaining waste will be used by cement plants to produce energy.

Once again, Belgium is a strong performer in this area: the Belgian recycling rate is very high and far exceeds the legal requirements, which impose a reuse rate of at least 55%.

And there’s more...

Febelauto collects all the data needed to allow traceability and continuous improvement. The non-profit organisation leads the way in maintaining a dialogue between the different interest groups and the three regions. Furthermore, constantly reflecting on issues opens up the door to different projects and innovations, allowing circular fleet management to become even more efficient.